Students in the FCAW program will learn methods and introductory print reading for welding. FCAW processes allow for high quality welds, versatility, and out-of-position welding capability. Gage ability and horizontal/vertical welds are reviewed during this course. The FCAW process is used by manufacturers, industry, and in construction.

Students in the GMAW, commonly known as MIG (Metal Inert Gas), program will learn methods and introductory print reading for welding. GMAW processes are used by industry, maintenance repair, and hobbyist. Spray transfer mode, short circuit, and metal art are competencies within the course. GMAW is fast and economical and is used for welding thin-gauge metal as well as heavy plate.

Course schedules for the upcoming sessions are:

GMAW (MIG)- 6 sessions- spray transfer mode, short circuit, metal art

FCAW- 6 sessions- gage ability horizontal and vertical

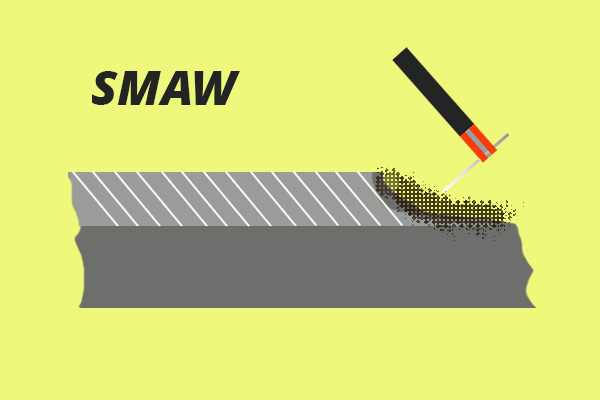

Students will learn the Shielded Metal Arc Welding (SMAW), or more commonly called “stick welding” process, methods, and introductory blueprint reading for welding. The SMAW process is used by industry for fabrication and repair.

This course is for personal interest, career exploration, or to add the SMAW method/qualification to your skillset. A career in welding requires a long-term commitment to studying, fabrication methods, and many hours of welding practice.